In the advanced medical and consumer electronic applications, from robotic medical arms to small AR/VR headsets, space is at a premium. Developers progressively depend on ultra-fine coaxial cables to transfer fast data as well as energy within these firmly loaded, dynamic assemblies. A crucial, however frequently misinterpreted, spec for these micro workhorses is the minimal bending radius. Surpassing this restriction can easily result in devastating signal failure. However, exactly what specifies this essential specification? It's not a single value, however, the complicated interaction of physics, products, and technical style.

The Core Conundrum: Material Stress and Strain

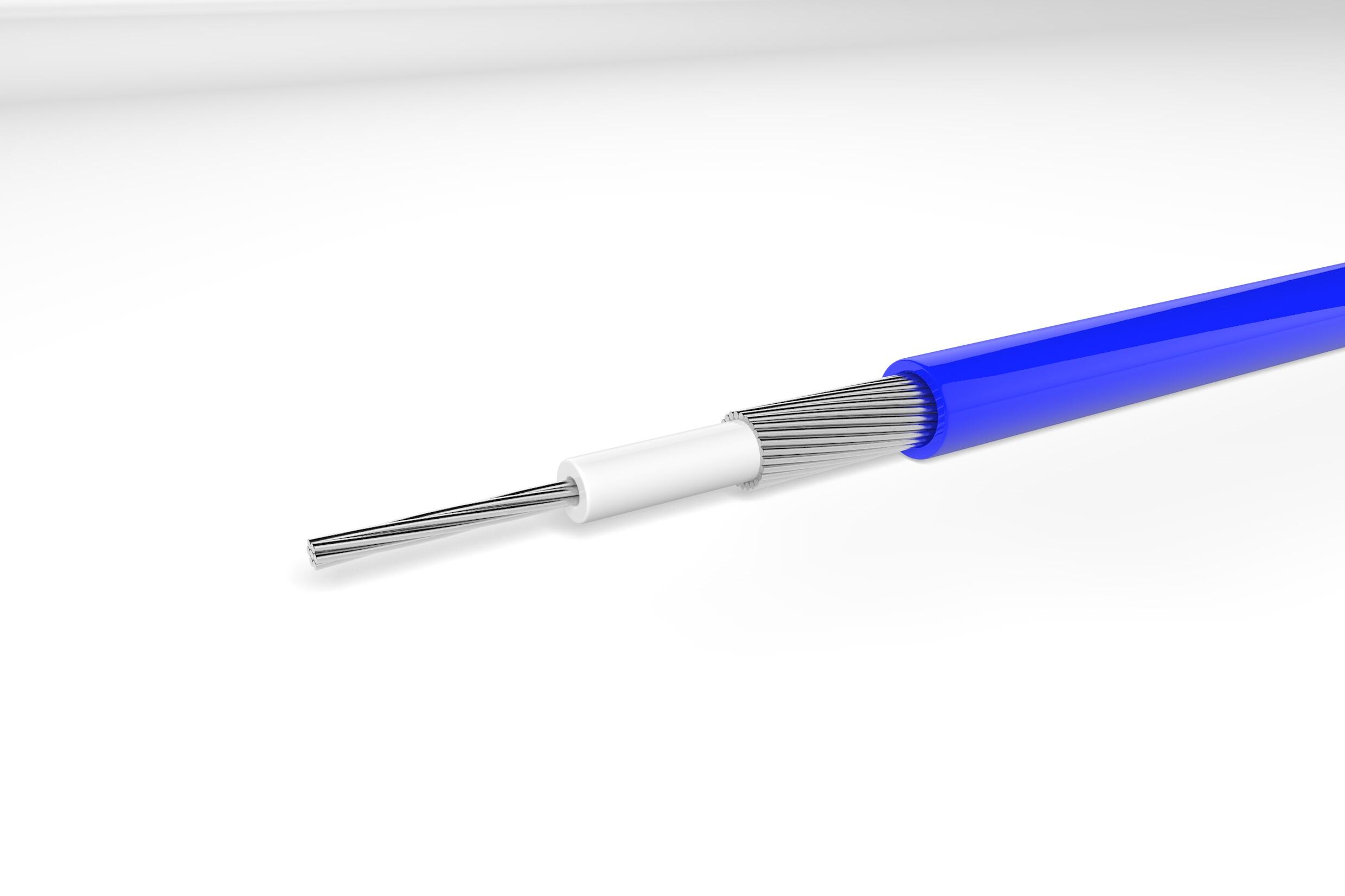

The essential restriction is governed through product science, specifically, stress and strain . When a cable is curved, its own external surface extends (tension), as well as its own internal surface compresses. For the main conductor, generally made from copper or even silver-plated copper, extreme as well as duplicated stress results in work hardeningas well as ultimate fatigue fracture. The thinner the conductor (such as AWG 44 or even finer), the much a lot extra severe this tension focus ends up being for a given bend radius. For that reason, the very initial definer of the bending radius is the ductility as well as tiredness protection of the conductor alloy, as well as its own stranding style. A carefully stranded conductor can easily withstand tighter flexes compared to a strong one, a concept crucial for the durability of Robotics Wire Harnesses as well as gimbal video cable harnesses, where movement is continuous.

The Dielectric Dilemma: Compression Set and Electrical Stability

Bordering the conductor is the dielectric protection. This product should certainly not just be versatile but also durable. When curved as well dramatically, smooth dielectrics can easily go through long-term contortion (compression set), producing a weaker factor that alters the cable's geometry. This contortion modifies the crucial range between the facility conductor and the guard, disrupting the managed impedance, a can severely affect signal integrity in USB4 cable harnesses or even LVDS cable harnesses for 4K endoscopes. The bending radius should be sufficiently large to guarantee the dielectric springs return to their own initial form, preserving a steady stable electrical performance over repeated bending cycles.

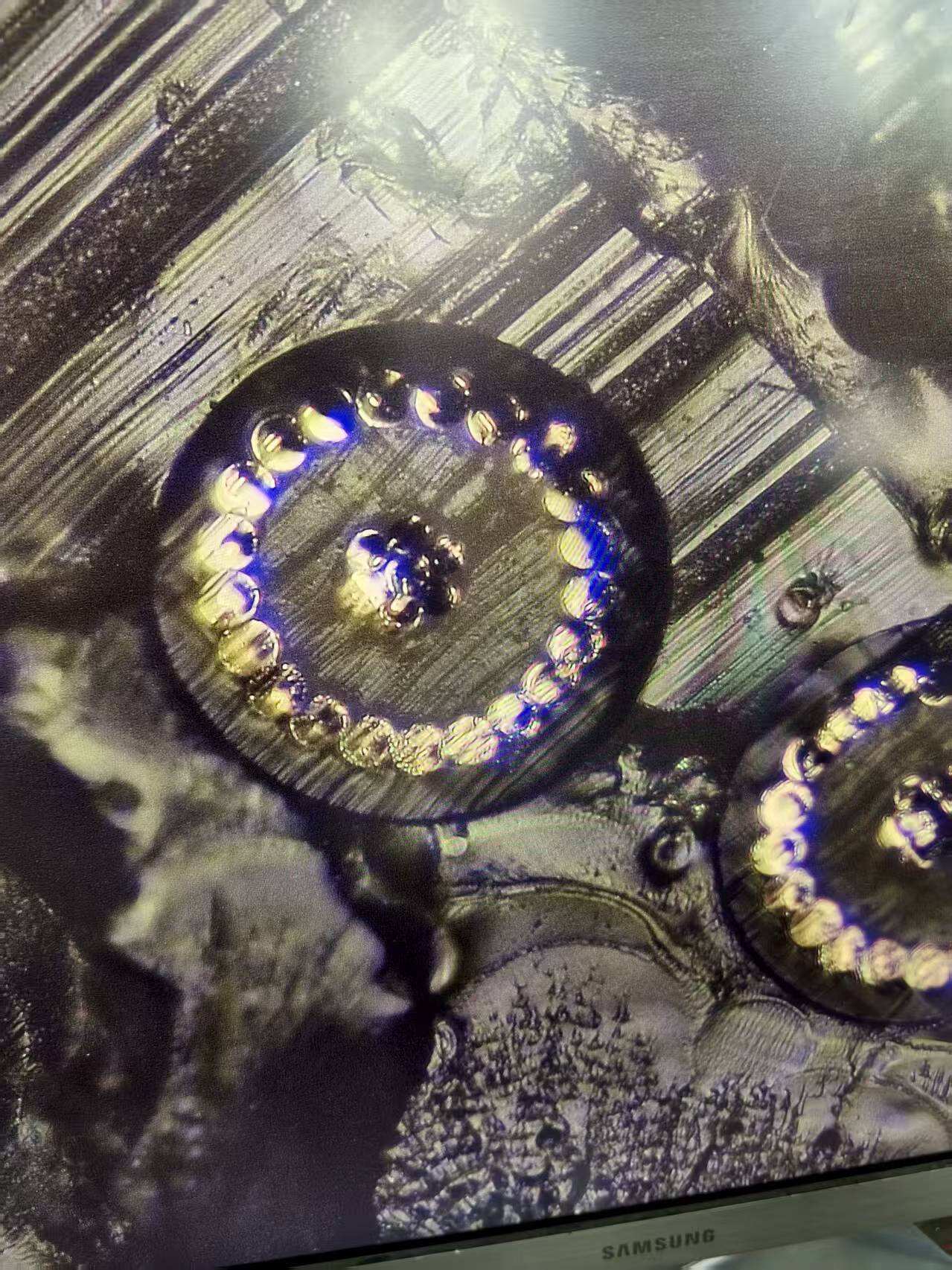

The protective layer is one of the most susceptible to bending damage. A foil guard can easily break as well as different, while a penalty intertwined or even offered guard can easily struggle with damaged hairs as well as enhanced electric protection under limited, duplicated bending. A jeopardized guard significantly enhances signal attenuation as well as electromagnetic interference (EMI) vulnerability, enabling sound to interfere with sensitive signals in EEG top cables or even enabling discharges coming from RF ablation cables to disrupt other devices. The minimal bending radius is specified due to the factor at which the shield's design starts to deteriorate, shedding its own 100% protection as well as background effectiveness. This is an essential factor to consider in the style of our ultrasound probe cables as well as endoscope cables.

The System Synergy: Jacket, Lay, and Application-Specific Demands

Lastly, the bending radius is specified due to the finished cable setting up. A tough coat product can easily assist disperse tension, however might also limit motion if as well rigid. Much more significantly, in a multi-conductor assembly (typical in ICE cables or even IVUS cables), the interior lay geometry is essential. A regulated, helical lay enables private cables to relocate about one another throughout a bend, producing a neutral axis that reduces private conductor stress. The supreme restriction is determined due to the most demanding problem: Is it a single setup bend or even a vibrant bending pattern over countless movements? The appropriate radius for a fixed oral noticing cable will certainly be much smaller compared to that of a continuously articulating medical robotic harness.

At Hotten Electronic Wire Technology, minimum bending radius is defined through conductor design, dielectric selection, shielding structure, and dynamic fatigue validation testing. With a precise choice of conductor stranding, dielectric polymers, guard design, as well as general assembly style, our team specifies as well as validate bending frontiers that guarantee long-lasting dependability and signal stability. For our customers in medical as well as modern markets, this implies a cable service that suits their type of element without risking the efficiency that specifies their product.

Hot News

Hot News2025-12-17

2025-12-11

2025-12-05

2025-04-29