High-frequency signals generally refer to electrical signals above 1 MHz. In modern applications, many scenarios now operate well into the GHz range. For example, 5G RF signals can exceed 60 GHz, and PCIe protocols commonly used in high-speed servers also reach extremely high transmission frequencies. As the operating frequency continues to increase, the requirements for cable materials, electrical characteristics, and structural design become significantly more stringent. This makes high-frequency transmission one of the most sensitive application scenarios for conductor performance.

In these applications, commonly used high-frequency cables include:

● Micro-coaxial cables (38–46 AWG)

● RF coaxial cables (20–36 AWG)

● High-frequency high-speed differential pairs (LVDS / USB / HDMI / PCIe)

These cables are widely used in equipment requiring high-speed data and high-definition image transmission, such as server racks, UAV video transmission links, industrial cameras, imaging modules, and medical ultrasound systems. Because these applications require high signal integrity, large bandwidth, and strong anti-interference performance, the selection of cable materials and precision of structural control directly determine the final transmission quality.

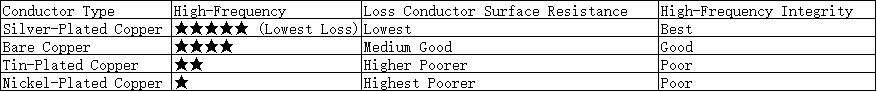

The key factors affecting high-frequency signal transmission mainly come from the conductor, insulation, and shielding. Among them, conductor materials vary significantly in electrical conductivity—silver has the highest conductivity, followed by copper, with aluminum and alloys being lower. The surface structure, smoothness, and roughness of the conductor also have a substantial impact on high-frequency loss. For insulation materials, the lower the dielectric constant (Dk) and dissipation factor (Df), the better the cable can reduce signal attenuation. In addition, shielding structures (such as single-wrap, double-braid, or foil + braid) and dimensional consistency of the cable diameter further influence impedance control and EMI resistance. Together, these factors determine the overall transmission quality of high-frequency cables.

In high-frequency environments, one important physical phenomenon greatly affects signal performance — the skin effect.

What is the skin effect?

As the signal frequency increases, the distribution of current inside the conductor changes. Effective current becomes more concentrated on the outer surface of the conductor rather than flowing through its entire cross-section. This means that the resistance of the conductor surface determines the magnitude of high-frequency loss. The higher the frequency, the more the current “only flows on the surface,” making the surface material and its conductivity the most critical factors for high-frequency performance.

Because of the skin effect, high-frequency current primarily flows along the outer layer of the conductor. Silver, being the most conductive metal (106% IACS), becomes the most efficient conductor plating material for improving high-frequency performance. By plating a layer of silver onto a copper conductor (typically above 0.3 μm depending on application), the effective surface resistance can be significantly reduced, allowing high-frequency signals to pass with lower loss and greater stability. As a result, copper conductors with silver plating have become the most widely adopted and cost-effective solution in high-frequency cable design—an outcome supported by theory, test data, and practical manufacturing economics.

Test results from the industry demonstrate that silver-plated copper conductors exhibit significantly lower insertion loss at high frequencies compared with bare copper, tin-plated copper, or nickel-plated copper. The benefits brought by silver plating include reducing high-frequency attenuation by 10–20%, improving long-distance transmission stability, enhancing image clarity with lower noise, minimizing EMI radiation, and delivering better resistance to temperature-induced resistance changes. Silver plating also offers superior oxidation resistance. These advantages are particularly noticeable in imaging-related applications such as UAV video links, industrial cameras, endoscopes, and medical imaging systems, where high-frequency attenuation directly affects image quality. In such cases, silver plating provides clear and measurable performance improvements.

Among the many cable manufacturers using silver-plated copper conductors, Hotten Cable—based in Suzhou, Jiangsu—is a well-established company with comprehensive design and manufacturing capabilities in the high-frequency cable field. Hotten supports the production of ultra-fine 40–50 AWG signal transmission cables and offers low-dielectric, high-frequency insulation extrusion processes including PFA, PTFE, and foamed PFA. These advanced design and manufacturing capabilities ensure excellent product stability. Hotten's coaxial cables are widely used in medical ultrasound equipment, UAV video transmission systems, industrial endoscopes, camera modules, and various other applications that require high-frequency stability. Furthermore, Hotten provides complete cable and cable-assembly solutions covering conductor design, insulation, shielding, and structural configuration—allowing customers to obtain the optimal material combination and structural design for their specific high-frequency transmission needs.

Hot News

Hot News2025-12-17

2025-12-11

2025-12-05

2025-04-29