I. Why Does Stuttering Occur? — Excessive Signal Attenuation

In scenarios such as high-speed data transmission, image signal return, audio acquisition, medical imaging, drone image transmission, and high-frequency communication, signal stuttering, image latency, audio desynchronization, and data instability are among the most common pain points. One of the core reasons behind these phenomena is signal attenuation.

In high-frequency environments, the stability of signal transmission largely depends on the dielectric constant of the insulating material. The higher the dielectric constant, the faster the signal is lost in the material; the lower the dielectric constant, the lower the attenuation, and the more complete the signal.

II. Commonly Used Low-Dielectric Material in the Industry: PFA

Among many insulating materials, PFA, with its low dielectric constant of approximately 2.1, excellent high-frequency stability, and temperature resistance, has become the industry-recognized mainstream material for high-frequency cables, widely used in RF cables, high-speed data cables, medical imaging cables, and image transmission cables.

III. Foamed Cable Technology Based on PFA Material

To achieve even lower signal attenuation, physical foaming can be used in PFA. Foamed cables utilize a nitrogen injection extrusion process to form closed spherical cells (0.006-0.033 mm) within the insulation layer. These micro porous structures further reduce the dielectric constant. The dense, uniform, and stable structure avoids the deformation problems of traditional insulation materials, while also reducing cable weight, improving flexibility, and optimizing high-frequency loss performance.

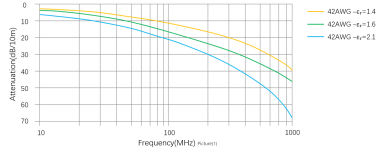

Currently, commercially available foamed PFA typically achieves a foaming degree of 45%-55%, further reducing the dielectric constant to around 1.4 and decreasing signal attenuation (see Figure 1 below). This enables ultra-high-speed data transmission with extremely low distortion, ensuring signal integrity in high-frequency applications. Simultaneously, its self-sheathing properties ensure good adhesion between the insulation layer and the conductor, reducing return loss.

IV. Performance Advantages of Foamed Cables

1. Lower dielectric constant → Lower attenuation, significantly improved signal integrity

2. Lighter insulation layer → More flexible structure, suitable for microcoaxial and multi-core cables

3. Closed microporous structure → More stable impedance, lower return loss

4. Higher bandwidth margin → Suitable for long-distance, ultra-high-speed signal transmission

V. HottenCable's Manufacturing Capabilities: Mass Production of 40–46AWG Ultra-Fine Coaxial Cables

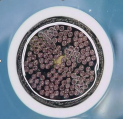

Leveraging foamed materials and mature foaming extrusion technology, HottenCable has achieved stable mass production of 40AWG~46AWG ultra-fine coaxial cables.

Currently, they are mainly used in medical ultrasound imaging cables, such as 132-core ultrasound cables. The image below shows an ultrasound cable and its cross-section:

Hotten Cable also provides low-loss RF cables, ultra-fine coaxial cable bundles, impedance-controlled bundles, multi-core medical imaging cables, and other customized high-speed transmission solutions.

Hot News

Hot News2025-12-17

2025-12-11

2025-12-05

2025-04-29