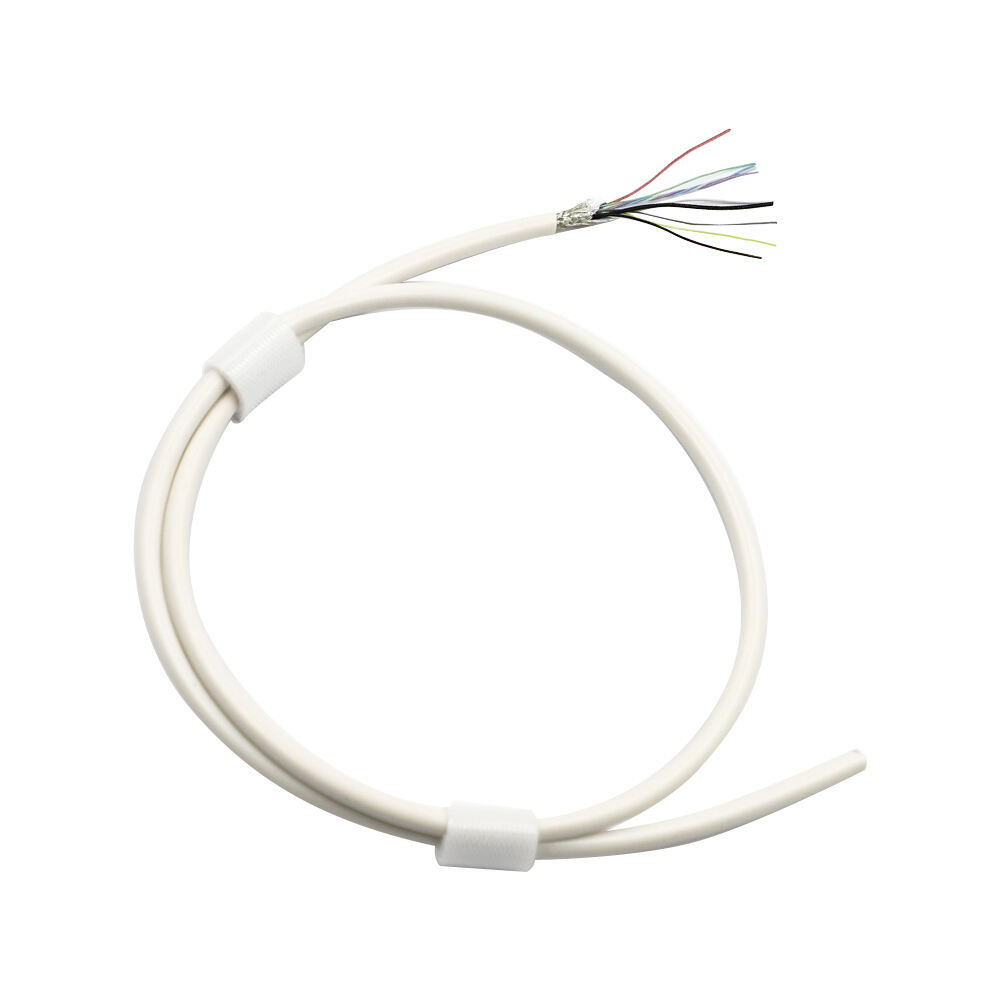

40AWG Micro Coaxial Harness Interface 20680 30/40P Custom Cable Assembly for Displays

| Product: | 40AWG Micro Coaxial Cable Assembly |

| Certifications: | Rohs,Reach compliant;ISO9001/ ISO13485 factory management |

| Applications: | Displays EDP LVDS |

| Customization: | Cable length & core count, Connector type (JAE / I-PEX / Customized) |

| MOQ: | 1 pcs |

| Trade terms: | FOB Shanghai / Ningbo, EXW Suzhou, etc. |

- Overview

- Recommended Products

- Optimized for eDP / LVDS Notebook & TV Panels

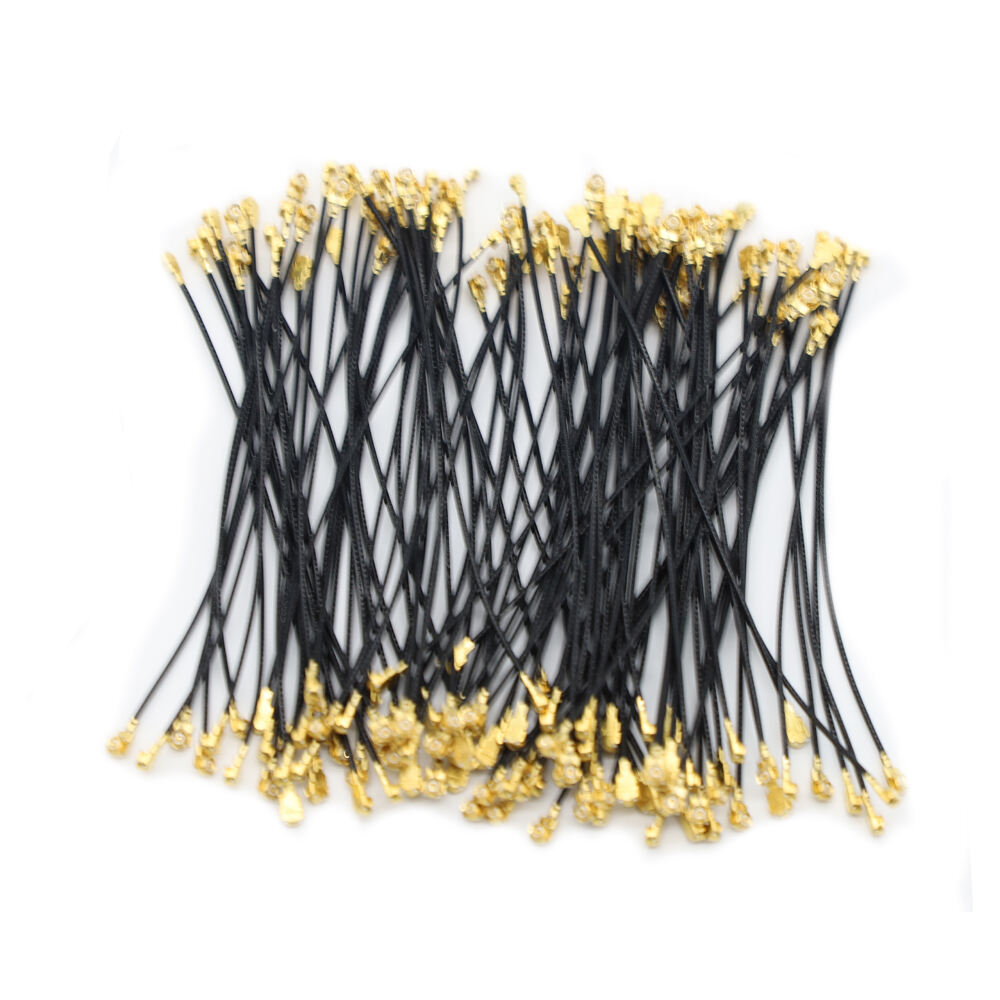

- Genuine I-PEX 20680 30/40P Micro-Coax Connector

- Ultra-Fine 40AWG Micro Coax for Slim Hinge Routing

- Custom Length & Pin Assignment for OEM Projects

Specifications:

| Cable AWG: | 40AWG | |

| Number of cores: | 7 | |

| Application: | Application | EDP LVDS screen panel |

| Device | NoteBook PC/TV | |

| Connector | Brand | I-PEX |

| Position | Panel-side / Board-side (eDP / LVDS interface) | |

| Pin Count | 30P / 40P | |

| Sample | Available | |

Applications:

Advantages:

FAQ:

1. Q: How thin can your medical equipment cables be?

A: Our cables can reach an outer diameter as small as 0.25mm while maintaining excellent shielding and signal integrity.

2. Q: Do you produce cables in-house?

A: Yes, we have full in-house capabilities for extrusion, braiding, cabling, and testing to ensure consistency and reliability.

3. Q: What impedance values are available?

A: Standard options are 50Ω or 75Ω, with custom configurations available.

4. Q: What is the impedance tolerance?

A: ±2Ω, ensuring reliable high-speed signal transmission.

5. Q: Do you support multi-core parallel structures?

A: Yes, multi-core or hybrid assemblies can be customized.

6. Q: What outer jacket materials are available?

A: Common materials include FEP, PFA, PVC, TPU, and PEEK, depending on temperature and flexibility needs.

7. Q: Do you support custom specifications?

A: Yes, impedance, diameter, length, shielding structure, and color can all be customized.

8.Q: Can you provide drawings or design recommendations?

A: Yes, we provide structure and layout suggestions based on electrical and mechanical requirements.

9. Q: What conductor materials are available?

A: Common materials include silver plated copper, tinned copper, silver plated copper alloy, tinned copper alloy, depending on the cable characteristics.

10.Q: What is the sample lead time?

A: Typically 10-15 working days, up to 3 weeks for complex structures.

11.Q: Do you have UL certification?

A: Some models are UL-certified, and all can be designed to meet UL standards.