အချိန်တစ်ခုမှာ ဆရာဝန်ကြီးများနှင့်သူများသည် ပုဂ္ဂိုလ်များကိုကြိုဆိုရန်အတွက် သုံးစွဲသည့် ယန္တရားများတွင် ဒီဇိုင်းအသစ်ကို တွေ့ရပါမည်။ ယနေ့ခေတ်တွင် ဆရာဝန်ကြီးများသည် ပုဂ္ဂိုလ်များကိုကြိုဆိုရန်အတွက် ထိုကဲ့သို့သော ကွန်ပျူတာများကို အသုံးပြုသည်။ ဆရာဝန်ကြီးများနှင့်သူများသည် ပုဂ္ဂိုလ်များကိုကြိုဆိုရန်အတွက် ယန္တရားများတွင် ထိုကဲ့သို့သော ကွန်ပျူတာများကို အသုံးပြုသည်။

ဆေးရုံတွင် သုံးစွဲသည့် ကဘယ်အစုံသည် အလွန်ပြီးစီးမှုနှင့် ချိန်သတ်မှတ်ထားသည်။ ဒါပေမယ့် အနည်းဆုံးအချက်အလက်အထိလည်း အလွန်ပြီးစီးဖြစ်ရမည်။ မှားယွင်းချက်ရှိလျှင် လူသား၏ ကျန်းမာရေးအတွက် အကြောင်းကြီးများဖြစ်နိုင်သည်။ ထို့ကြောင့် ကဘယ်များကို ပြီးစီးစွာ ဖန်တီးရန်အတွက် အရေးကြီးဖြစ်သည်။

ပညာရေးကုန်များအတွက် လိုင်စင်ဆိုင်ရာ ကုဒ်များထုတ်လုပ်ခြင်း၏ အခြားသော အရေးကြီးသော ဒေသတစ်ခုဖြစ်သည်။ အရည်အချင်းတစ်ခုစီကို မှန်ကန်သော လိုင်စင်များဖြင့် ထုတ်လုပ်ခြင်းဖြင့် အဲဒါတွေကို တူညီသောနည်းလမ်းဖြင့် ထုတ်လုပ်ခြင်းဖြစ်သည်။ ဒါဟာ အမှားယုံကြည်မှုများကို အရေးကြီးသော အဆုံးဖြတ်ချက်များရှိနိုင်သည်၊ ထို့ကြောင့် လူမှုရဲ့ အားကို ကာကွယ်ရန်အတွက် အရေးကြီးသည်။

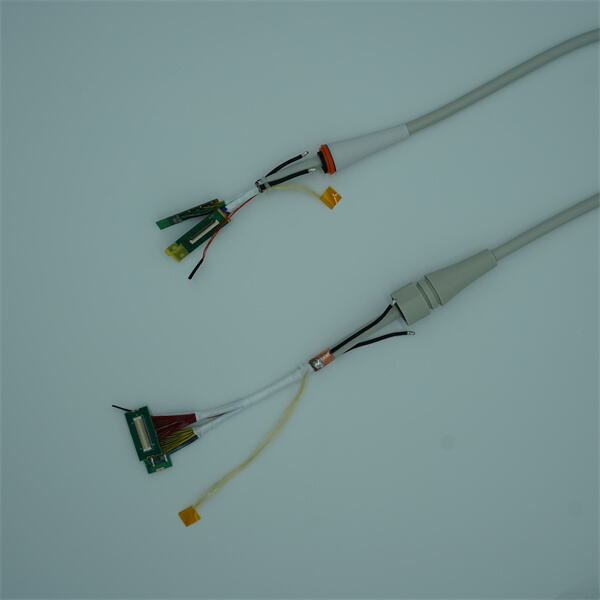

ဆေးရုံဝန်ထမ်းများသည် လူသား၏ ကျန်းမာရေးပြဿနာများကို ရှာဖွေရန် လက်ထဲတွင် ကိရိယာများပါသော ကိရိယာများကို အသုံးပြုသည်။ ဆေးရုံတွင် ကုန်ပစ္စည်းအသစ် ဖြန်ချိုးထုတ်လုပ်သူ ထိုကိရိယာများတွင် အသုံးပြုသည်။ X-ray ကိရိယာများ၊ ultrasound ကိရိယာများ၊ blood pressure ကိရိယာများတွင် တွေ့ရှိနိုင်သည်။ ဒီကိရိယာများသည် သူငယ်ချင်းများအား လိုအပ်သော အချက်အလက်များကို ပေးရန်အတွက် အထူးကဘယ်များလိုအပ်သည်။

ဆေးရုံခွဲတွင် အသုံးပြုသည့် ကဘယ်လ်အစီးအစဉ်ဆိုင်ရာ နည်းပညာတွင် ပေါ်ထွက်လာသည့် အသစ်များသည် လူမှုဝင်ရိုးကို ပိုမိုကောင်းမွန်စေရန်အတွက် တိုးတက်လျက်ရှိသည်။ HOTTEN အတိုင်း အများစုသော ကုမ္ပဏီများသည် ထိုကဘယ်လ်များ၏ အာရှုမှုနှင့် လုပ်ဆောင်မှုကို တိုးတက်ရန် အသစ်များကို ရှာဖွေလျက်ရှိသည်။ (ဒီဟာ အားလုံးအတွက် ပိုကောင်းမွန်သော ဆေးရုံဝန်ဆောင်မှုကို ရရှိစေရန်အတွက် အသစ်များသော ပစ္စည်းများနှင့် ဒီဇိုင်းများကို အသုံးပြုခြင်းဖြစ်သည်။)