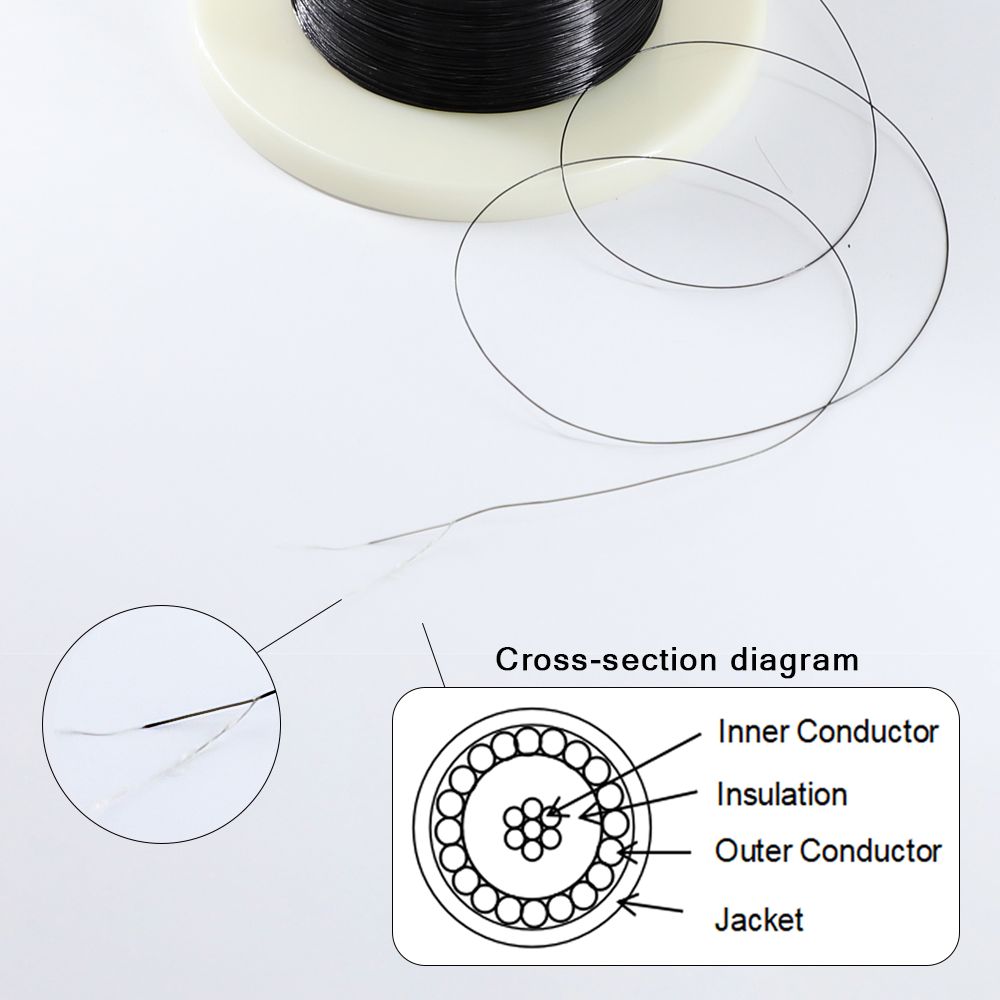

In the relentless push for miniaturization throughout industries, from high-density medical probes to next-generation AR/VR cables, engineers progressively rely on ultra-fine conductors such as AWG 50 micro coaxial cables. With an outer diameter of approximately 0.025 inches (0.635 mm), these cables allow amazing form factor reductions. Nevertheless, running at higher uniformities on such a small range presents unique physical difficulties, mainly signal loss. Comprehending the physics responsible for this reduction is crucial for effectively releasing all of them in delicate applications like ICE, IVUS, as well as oral imaging cables.

Conductor Loss in AWG 50 Micro Coax Cables at Low Frequencies

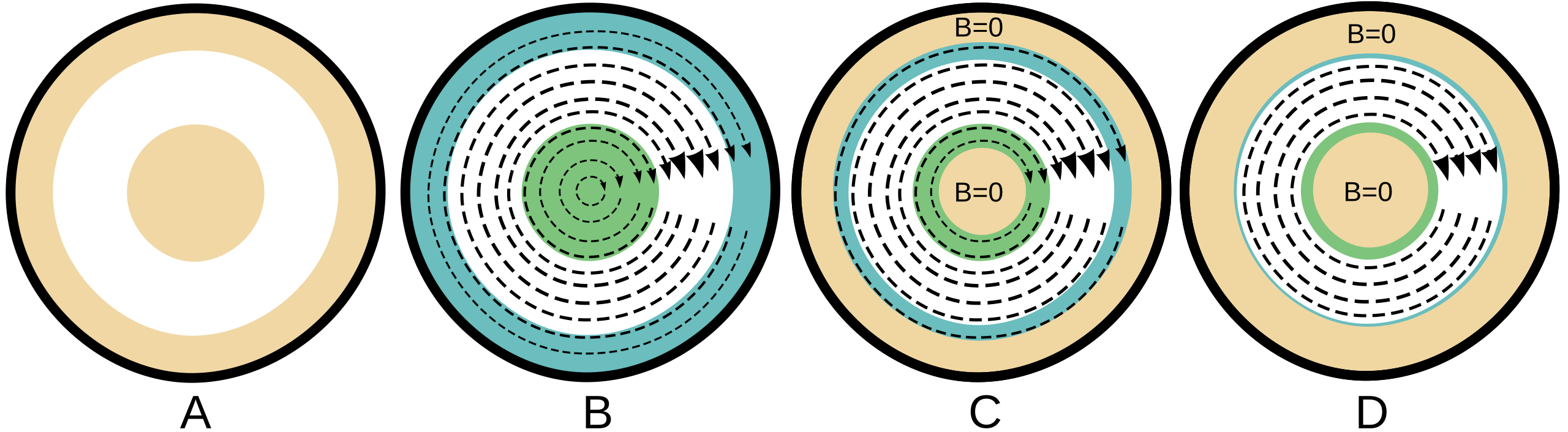

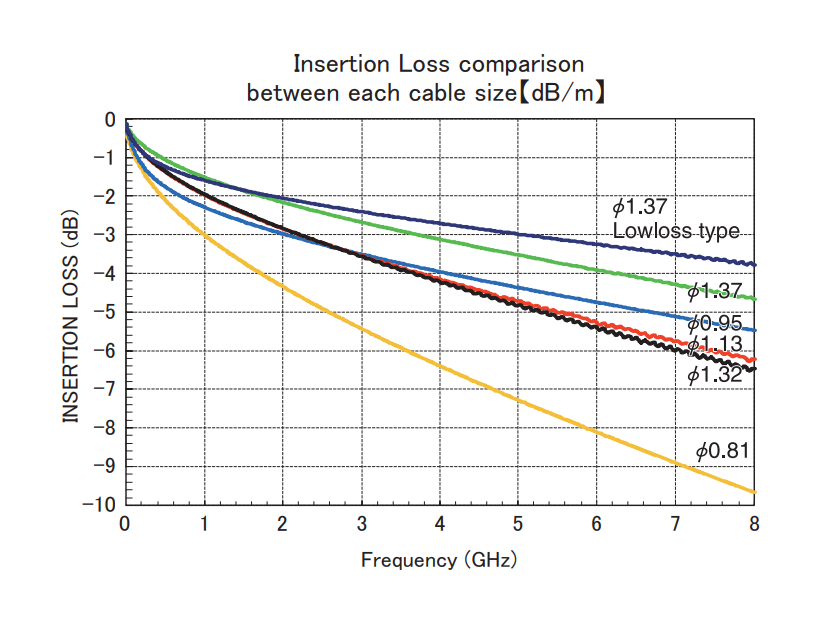

The main source of loss in any form of coaxial cable is conductor loss, caused by the skin layer impact. As signal frequency increases, current flow is confined to a thin "skin" layer at the conductor's surface. The skin depth (δ) is inversely proportional to the square root of frequency and conductor permeability. For an AWG 50 cable, the small conductor cross-section provides a serious restriction: the high-frequency resistance of such small conductors is primarily larger since the offered surface area for present flow is very little. This leads to considerable Ohmic (I²R) losses, where electric power is transformed to heat. In applications such as dense Drone Wire Harnesses or even Robotics Wire Harnesses, where cable operation could be brief, however, packages are incredibly limited, managing this conductive heating is essential to prevent performance degradation.

Dielectric Loss in AWG 50 Micro Coax Cables at High Frequencies

While conductor loss controls at reduced frequencies, dielectric loss ends up being progressively considerable as frequencies climb up right into the multi-gigahertz variety. This loss happens within the insulating product (dielectric) dividing the facility conductor coming from the guard. When an alternating electric field is applied, polar molecules within the dielectric material continuously realign, producing rubbing as well as heat; this is the dissipation factor (Df). Ultra-fine cables need ultra-thin dielectrics, which frequently implies material trade-offs. Choosing a dielectric along with a reduced dissipation factor (such as broadened PTFE) is non-negotiable for protecting signal stability in high-bandwidth applications like USB4 Cable Harnesses, as well as LVDS Cable Harnesses for high-resolution medical screens.

Structural Return Loss and Impedance Discontinuities in Ultra-Fine Micro Coax Cables

Signal loss is not only about attenuation, but also about signal reflections. Structural Return Loss (SRL) is triggered by minute flaws in the cable's geometry, variations in the size of the dielectric, eccentricity of the facility conductor, or even inconsistencies in the guard braid. In an AWG 50 cable, where tolerances are determined in microns, any form of discrepancy triggers a impedance discontinuity. These discontinuities trigger a part of the signal to show rear to the resource, efficiently reducing the transmitted signal power as well as triggering information mistakes or even image artifacts. This is especially crucial for ultrasound probe cables and endoscope cables, where analog RF signal integrity straight associates to picture clarity as well as diagnostic confidence.

Mitigation Through Precision Engineering and Material Science

Conquering these physical restrictions needs an alternative design method:

Advanced Materials: Utilizing high-purity, silver-plated copper conductors makes the most of surface conductivity. Utilizing low-density, low-Df dielectrics reduces polarization losses.

Precision Manufacturing: Preserving micrometer-level tolerances in extrusion as well as cabling guarantees geometric uniformity, managing resistance, and reducing SRL. This accuracy goes to the center of our RF coaxial cable as well as micro coaxial cable assembly manufacturing.

Optimized Design: Comprehending the application's frequency band enables customized styles. For example, a Gimbal Camera Wire Harness may focus on versatile, low-loss dielectrics for duplicated motion, while an RF Ablation Cable should balance very little signal loss along with high-power shipment ability.

For OEMs pressing the limits of innovation, the option of an ultra-fine coaxial cable is a balance of physics as well as efficiency. At Hotten Electronic Wire Technology, our team designs our AWG 50 micro coaxial cables not simply to satisfy dimension restrictions, but also to proactively dominate the fundamental difficulties of signal loss. Through grasping the interaction of conductor geometry, dielectric properties, as well as structural accuracy, our team provides cables that guarantee dependable, high-fidelity signal transmission for one of the most progressed clinical, customer, and commercial applications.

Hot News

Hot News2025-12-17

2025-12-11

2025-12-05

2025-04-29