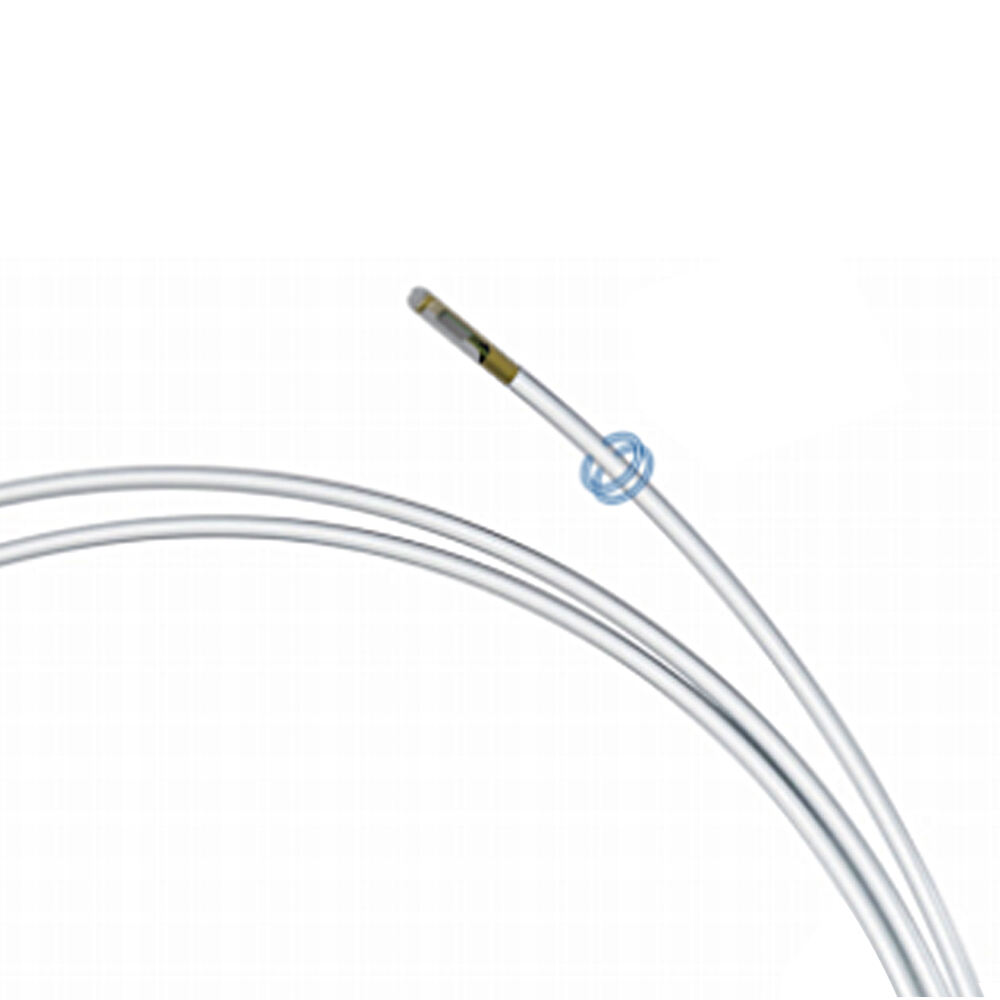

ဆေးဘက်ဆိုင်ရာ ကြိုးအစုအပုံ့ အလင်းမဲ့မီးခိုးရောင်ဂျက်ကတ် Molex နှင့် Ipex ကွန်နက်တာ ကြိုးဟာဍ်စ် အထူးပြုဝန်ဆောင်မှု

ဦးနှောက်အောက်စီဂျင် တိုင်းကိရိယာ ကြိုးဟာဍ်စ် Molex နှင့် IPEX ဂျက်ကတ်၊ အီလက်ထရောနစ်ကြိုး

| ကဗားဒ် ဖော်မြူ |

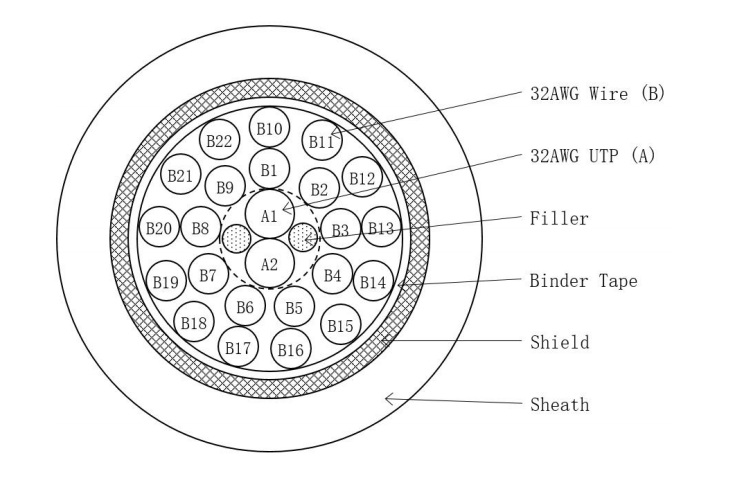

24C(1P×32AWG+22×32AWG)

|

| မောင်းသူ | Tinned copper |

| အလျင်းခြေထောင့် | Fep |

|

အင်မြစ်ကန်များမှ ထိခိုက်မှု ကန့်သတ်ခြင်း

|

Tinned copper |

|

အင်္ကျောင်း

|

ဆီလီကွန် |

| ပြင်ပ အချင်းအရှည် |

4.8±0.2 mm

|

| အရောင် |

မျက်နှာရောင်အလွတ်

|

| စိတ်ကြိုက်ဖြေရှင်းချက် |

ထောက်ခံသည်

|

- ဆီလျော်သော

- အကြံပြုထားသော ပစ္စည်းများ

- ပါးပါးနှင့် ကွေးညွှတ်နိုင်သော

- အနည်းဆုံး MOQ

- RoHS/Reach/ISO13485/ဇီဝဆိုင်ရာ ကိုက်ညီမှုတို့နှင့် ကိုက်ညီမှု

- ပေးဆောင်မည့်အချိန်မှ ရှုံးစစ်ခြင်း ၁၀၀%

- နည်းပညာအဖွဲ့မှ ၂၄ နာရီအတွင်း ကေဘယ်လ်အသေးစိတ်ဖော်ပြချက်/မှုတ်ပုံပေးနိုင်ခြင်း

- အူမြောင်းကြည့်ကိရိယာ ကေဘယ်လ်

- ဦးနှောက်သွေးအောက်ဆီဂျင် တိုင်းကိရိယာ ကေဘယ်လ်

- ခွဲစိတ်ကိရိယာ ကေဘယ်လ်

ကေဘယ်လ်လျှပ်စစ်ဂုဏ်သတ္တိများ

| ပစ္စည်း | ယူနစ် | အတိုင်းအတာ |

|

32AWG UTP(A) |

32AWG ဝိုင်ယာ (B) |

||

အမှတ်တင်အပူချိန် |

℃ |

80 | |

အားပေးစွမ်းအရာ |

V |

300 | |

ဒိုင်အက်လက်ထရစ် ခိုင်မာမှု |

AC.V/1min |

500 | |

ကွန်ဒပ်က်တာ ပြိုင်ဆန်မှု (20℃ တွင်) |

ω/km |

မဟုတ်ပါ။580 |

မဟုတ်ပါ။580 |

ကာကွယ်မှုပြိုင်ဆန်မှု (20℃) |

MΩ-km |

အနည်းဆုံး ၁,၀၀၀ |

အနည်းဆုံး ၁,၀၀၀ |

လျှပ်စစ်ခုခံမှု (2ns တွင်) |

ω |

ပုံမှန် 100 |

- |

ကေဘယ်လ်ဖြတ်ပိုင်း

အားသာချက်

အသုံးပြုမှု

မေးလေ့ရှိသောမေးခွန်းများ

၁။ မေး: သင့်တော်သော ဆေးဘက်ဆိုင်ရာ ပစ္စည်းကြိုးများ၏ အထွက်အချိုး အနှိမ့်ဆုံးမှာ မည်မျှရှိပါသလဲ။

ဖြေ: ကျွန်ုပ်တို့၏ ကြိုးများသည် 0.25mm အထိ အထွက်အချိုးရှိပြီး အကာအကွယ်နှင့် အချက်ပြမှု တည်ငြိမ်မှုကို ထိန်းသိမ်းထားနိုင်ပါသည်။

၂။ မေး: သင်တို့သည် ကြိုးများကို ကိုယ်ပိုင် ထုတ်လုပ်ပါသလား။

ဖြေ: ဟုတ်ကဲ့၊ တသမတ်တည်းဖြစ်မှုနှင့် ယုံကြည်စိတ်ချရမှုကို သေချာစေရန် ကျွန်ုပ်တို့တွင် အပြင်သန်းခြုံခြင်း၊ ကြိုးတိမ်ခြုံခြင်း၊ ကြိုးချိတ်ဆက်ခြင်းနှင့် စမ်းသပ်ခြင်းတို့အတွက် ကိုယ်ပိုင် စွမ်းရည်များ ပြည့်ဝစွာ ရှိပါသည်။

၃။ မေး: ရရှိနိုင်သော အခုန်တိုက်ခိုက်မှု တန်ဖိုးများမှာ မည်သည့်အရာများ ဖြစ်ပါသလဲ။

ဖြေ: ပုံမှန်ရွေးချယ်စရာများမှာ 50Ω (အိုမ်) သို့မဟုတ် 75Ω (အိုမ်) ဖြစ်ပြီး စိတ်ကြိုက် ပြင်ဆင်မှုများကိုလည်း ရရှိနိုင်ပါသည်။

၄။ မေး: အခုန်တိုက်ခိုက်မှု အမှားယွင်းမှု အတိုင်းအတာမှာ မည်မျှရှိပါသလဲ။

ဖြေ: ±2Ω (အိုမ်)၊ အမြန်နှုန်းမြင့် အချက်ပြမှု လွှဲပြောင်းမှုကို ယုံကြည်စိတ်ချရစေရန် ဖြစ်ပါသည်။

၅။ မေး: များခေါင်းပိုင်း အတူတကွ ဖွဲ့စည်းမှုများကို ပံ့ပိုးပေးပါသလား။

ဖြေ: ဟုတ်ကဲ့၊ များခေါင်းပိုင်း သို့မဟုတ် ရောစပ် တပ်ဆင်မှုများကို စိတ်ကြိုက် ပြင်ဆင်နိုင်ပါသည်။

၆။ မေး: အပြင်ချုပ်ပစ္စည်းများအနက် ဘယ်အမျိုးအစားတွေရနိုင်ပါသလဲ။

ဖြေ: အပူချိန်နှင့် ပျော့ပျောင်းမှုလိုအပ်ချက်များပေါ်မူတည်၍ FEP၊ PFA၊ PVC၊ TPU နှင့် PEEK တို့သည် အသုံးများသောပစ္စည်းများဖြစ်ပါသည်။

၇။ မေး: သင်တို့သည် စိတ်ကြိုက်အသွင်အပြင်အတွက် ပံ့ပိုးပေးပါသလား။

ဖြေ: ဟုတ်ကဲ့၊ အချိုးကျမှု၊ အချင်း၊ အလျား၊ ကာကွယ်မှုဖွဲ့စည်းပုံနှင့် အရောင်တို့ကို စိတ်ကြိုက်ပြင်ဆင်နိုင်ပါသည်။

၈။ မေး: ဇယားများ သို့မဟုတ် ဒီဇိုင်းအကြံပြုချက်များကို ပေးနိုင်ပါသလား။

ဖြေ: ဟုတ်ကဲ့၊ လျှပ်စစ်နှင့် ယန္တရားလိုအပ်ချက်များအပေါ် အခြေခံ၍ ဖွဲ့စည်းပုံနှင့် စီစဉ်မှုအကြံပြုချက်များကို ပေးနိုင်ပါသည်။

၉။ မေး: ဘယ်လိုကြိုးထဲကပစ္စည်းများကို ရရှိနိုင်ပါသလဲ။

ဖြေ: ကြိုး၏ဂုဏ်သတ္တိများပေါ်မူတည်၍ ငွေဖြင့်ပြုလုပ်ထားသော ကြေးနီ၊ သံမဏိဖြင့်ပြုလုပ်ထားသော ကြေးနီ၊ ငွေဖြင့်ပြုလုပ်ထားသော ကြေးနီပေါင်းစပ်ပစ္စည်း၊ သံမဏိဖြင့်ပြုလုပ်ထားသော ကြေးနီပေါင်းစပ်ပစ္စည်းတို့သည် အသုံးများပါသည်။

၁၀။ မေး: နမူနာကို ဘယ်လောက်ကြာအောင် ပြုလုပ်ပေးနိုင်ပါသလဲ။

ဖြေ: ပုံမှန်အားဖြင့် ၇ မှ ၁၀ ရက်ကြာ အလုပ်သက်တမ်း၊ ရှုပ်ထွေးသောဖွဲ့စည်းပုံများအတွက် ၂ ပတ်အထိကြာနိုင်ပါသည်။

၁၁။မေး: UL အထောက်အခံစိစစ်မှုရှိပါသလား။

ဖြေ: မော်ဒယ်အချို့သည် UL ဖြင့်အတည်ပြုထားပြီးဖြစ်ပြီး အားလုံးကို UL စံနှုန်းများနှင့်ကိုက်ညီစေရန် ဒီဇိုင်းထုတ်နိုင်ပါသည်။

ဇီဝဆိုင်ရာ သင့်တော်မှု