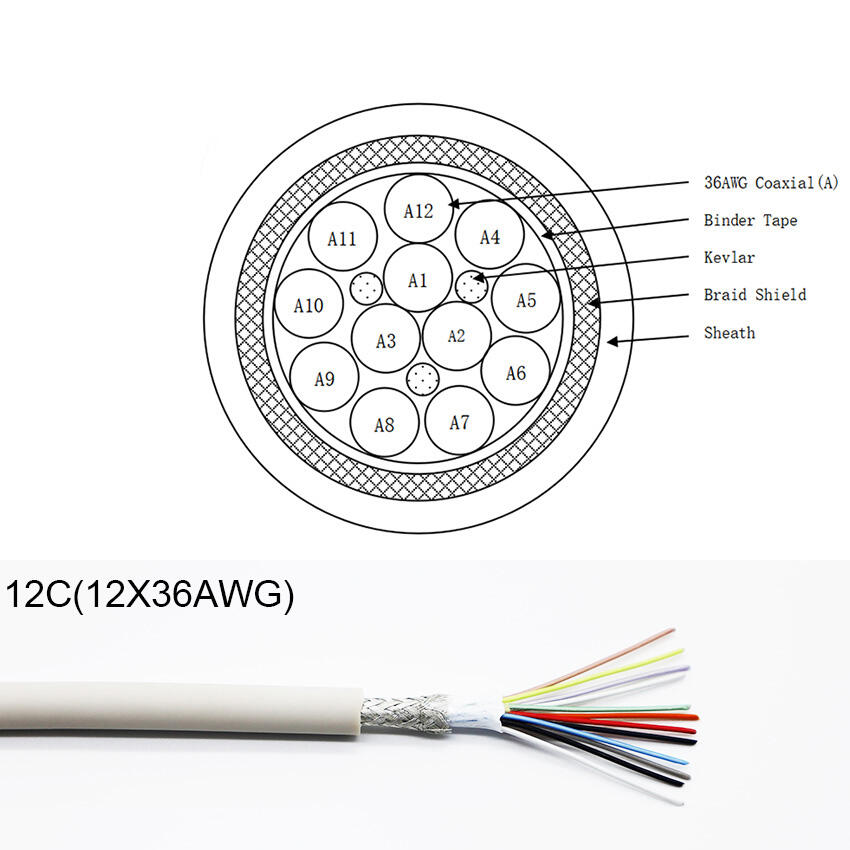

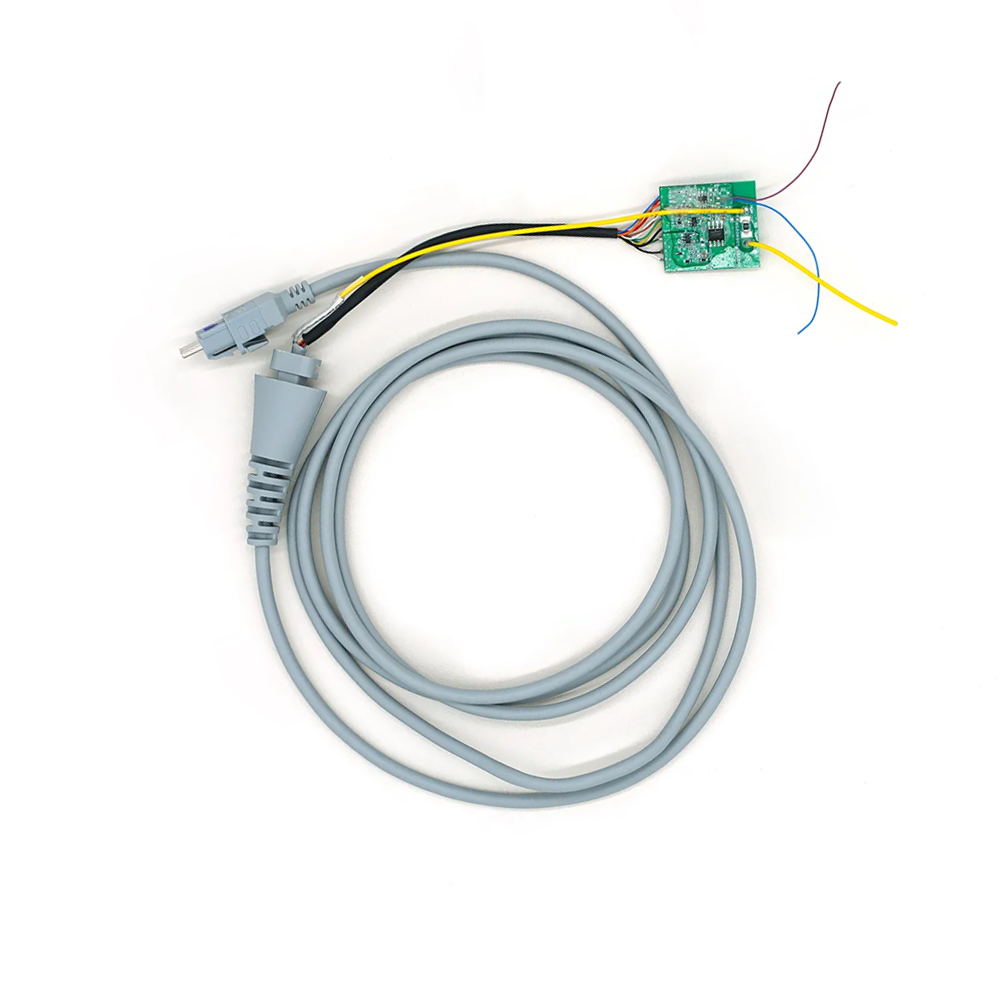

Hotten 12C(12X36AWG) PFA Jacket Micro Coaxial Cable Medical Ultrasound Probe Cable Ultrasound Cable for Opthamology

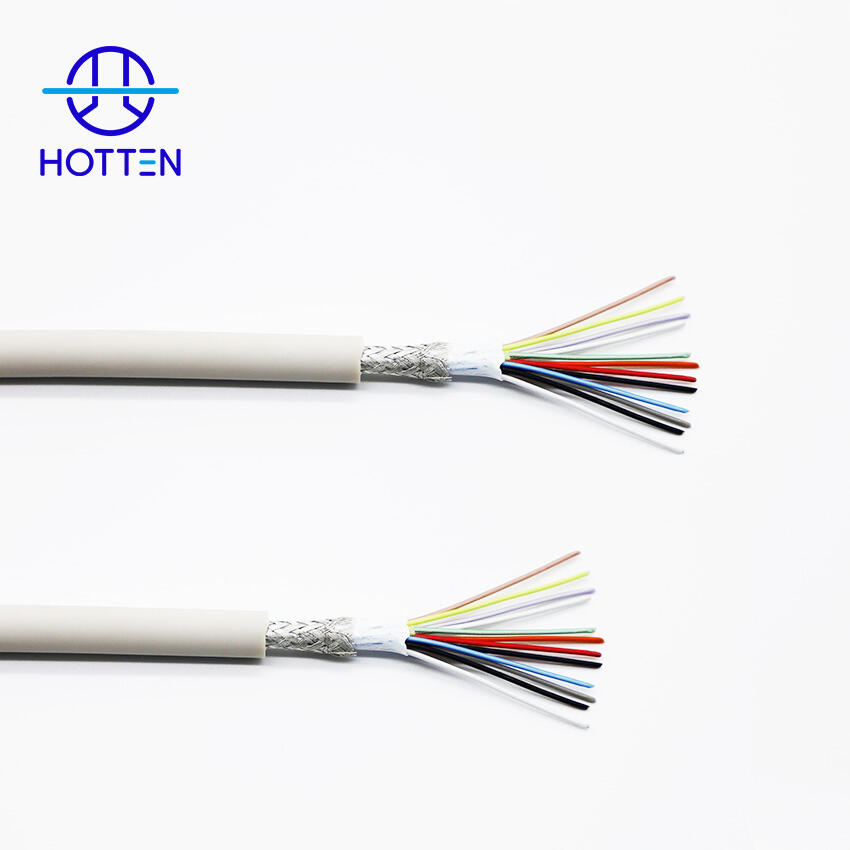

Product: 12C 36AWG Micro Coaxial Cable Medical Assembly

Certifications: Rohs,Reach compliant;ISO9001/ ISO13485 factory management

Applications: medical equipment,Ultrasound Probe Cable Ultrasound Cable

Customization: Cable length & core count

MOQ: 1 pcs

Trade terms: FOB Shanghai / Ningbo, EXW Suzhou, etc.

- Overview

- Recommended Products

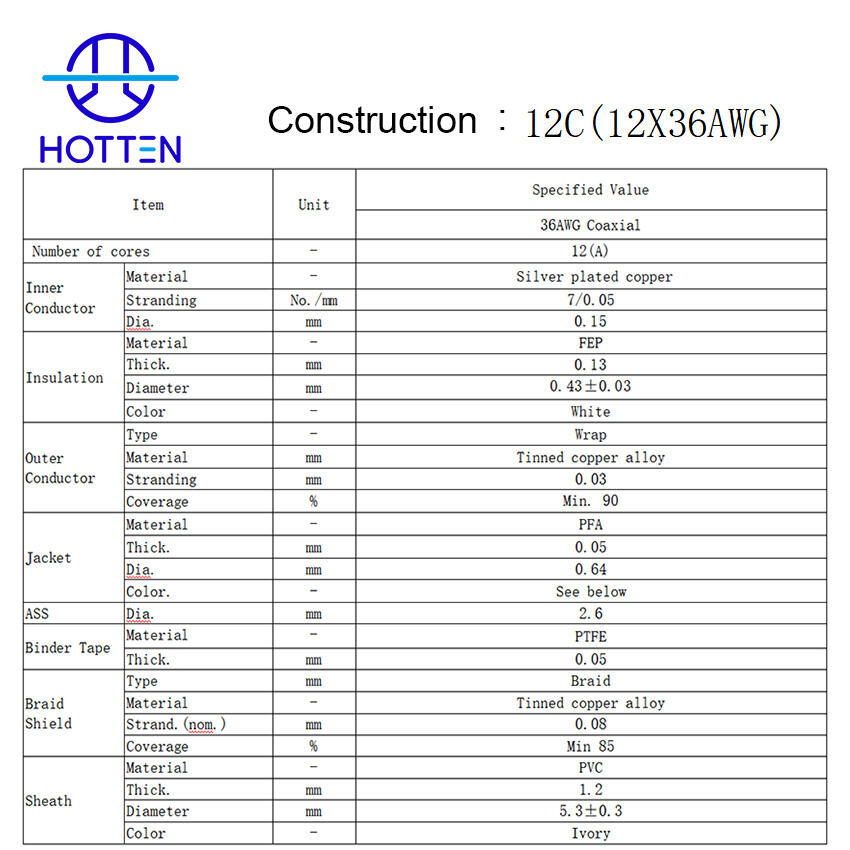

Specifications:

| Cable : | 12X36AWG |

| Application | Ultrasound Probe Cable Ultrasound Cable |

| Device | medical equipment |

| Inner Conductor | Silver plated copper |

| Insulation | FEP |

| Outer Conductor | Tinned copper alloy |

| Jacket | PFA |

| Braid Shield | Braid Tinned copper alloy |

| Sheath | PVC |

| Sample | Available |

Applications:

Advantages:

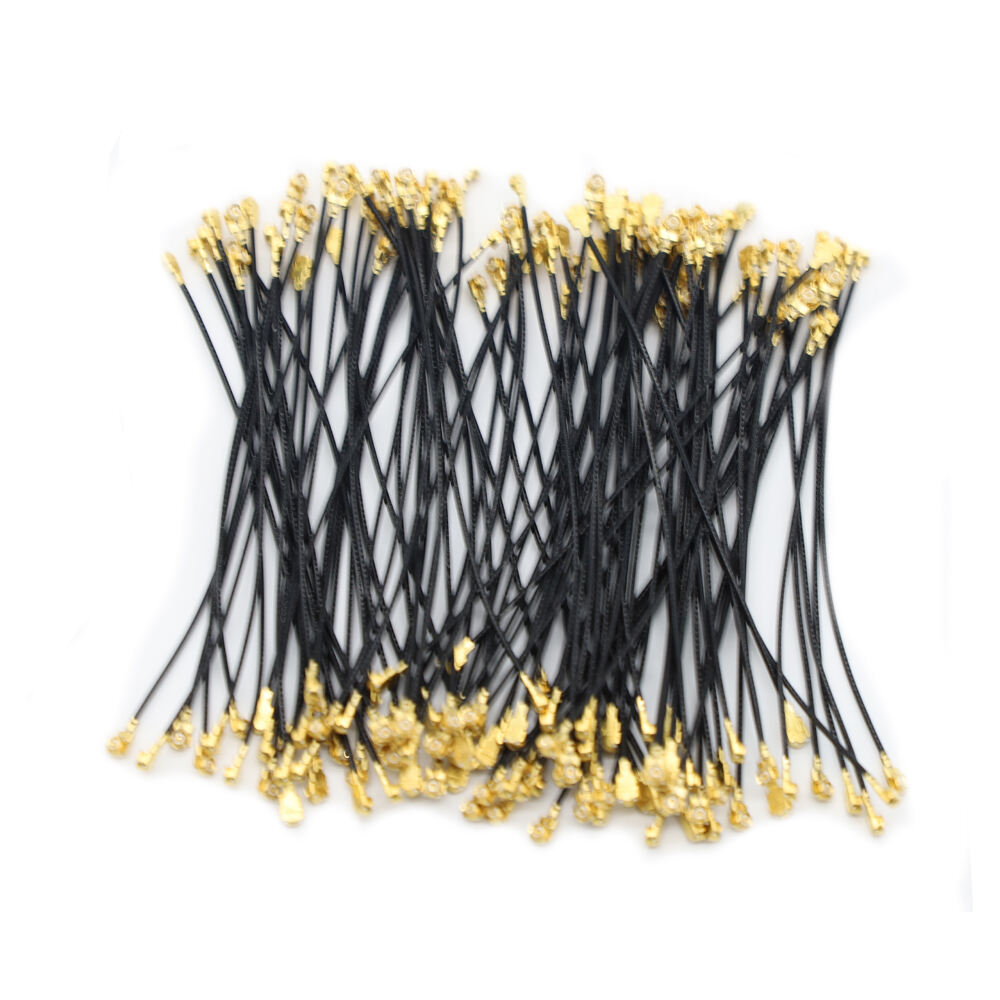

1. Ultra-Fine 36AWG Micro Coax Design for High-Resolution Ultrasound Imaging

The 12-core 36AWG micro coax structure provides excellent signal integrity, low capacitance, and high-frequency performance, ensuring clearer imaging and more accurate diagnostic results in ophthalmic ultrasound systems.

2. PFA Jacket for Superior Chemical, Heat, and Abrasion Resistance

The PFA outer jacket offers exceptional durability, biocompatibility, and resistance to disinfectants, making the cable ideal for frequent clinical cleaning and long-term use in medical environments.

3. Flexible and Lightweight Structure Designed for Probe Maneuverability

The cable’s micro-diameter construction ensures outstanding flexibility and ease of handling, improving operator comfort and enabling precise probe movement during ophthalmic examinations.

4. Customizable to Meet OEM Medical Device Requirements

Supports customization of length, impedance, shielding type, connector interface, and core configuration, ensuring seamless integration with various ultrasound probe models and medical imaging systems.

FAQ:

1. Q: How thin can your medical equipment cables be?

A: Our cables can reach an outer diameter as small as 0.25mm while maintaining excellent shielding and signal integrity.

2. Q: Do you produce cables in-house?

A: Yes, we have full in-house capabilities for extrusion, braiding, cabling, and testing to ensure consistency and reliability.

3. Q: What impedance values are available?

A: Standard options are 50Ω or 75Ω, with custom configurations available.

4. Q: What is the impedance tolerance?

A: ±2Ω, ensuring reliable high-speed signal transmission.

5. Q: Do you support multi-core parallel structures?

A: Yes, multi-core or hybrid assemblies can be customized.

6. Q: What outer jacket materials are available?

A: Common materials include FEP, PFA, PVC, TPU, and PEEK, depending on temperature and flexibility needs.

7. Q: Do you support custom specifications?

A: Yes, impedance, diameter, length, shielding structure, and color can all be customized.

8.Q: Can you provide drawings or design recommendations?

A: Yes, we provide structure and layout suggestions based on electrical and mechanical requirements.

9. Q: What conductor materials are available?

A: Common materials include silver plated copper, tinned copper, silver plated copper alloy, tinned copper alloy, depending on the cable characteristics.

10.Q: What is the sample lead time?

A: Typically 10-15 working days, up to 3 weeks for complex structures.

11.Q: Do you have UL certification?

A: Some models are UL-certified, and all can be designed to meet UL standards.